Sparkling Winemaking

Creation Date: Thursday August 29th 2019

Last Updated: Thursday August 29th 2019

I’ve come to regard anything that Bryce Rankin writes about winemaking is accurate, informative and practical. He is accessible to the interested amateur and this book is no exception. It is a text for makers of sparkling wines and those who have a general interest. It is a manual describing the production, from grapes to packaging. It is intended that a winemaker who has never made a bottle of sparkling could follow the process.

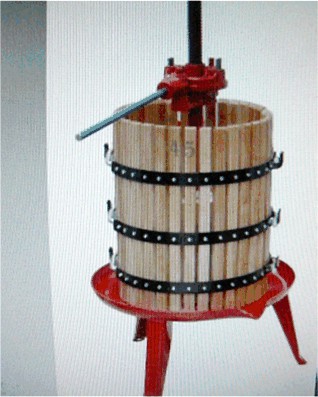

1. Liqueuring

In broad summary, once you have a base wine you put it into a bottle and inject with a sugar solution and start a secondary fermentation followed by crown-sealing the bottle. The conversion of sugar into alcohol and carbon dioxide results in a fizzy wine, made cloudy by dead yeast cells. You encourage the deposits to collect under the crown seal, and discharge the plug of sediment wine to waste. The resultant wine is then sugared to taste, sulphured to stop further fermentation and sealed once again. I guess it can get a bit more complicated than that, so read the book.

I made my first sparkling wine armed with just this set of knowledge and it tasted OK, so don’t get put off by the complexities that the professionals must master.

I will ignore most of the process and concentrate on the important information I was lacking when I made my first attempts: the liqueur and liqueuring. Two types of Liqueur are required: the one before secondary fermentation to produce CO2 in the bottle, and the liqueur to sweeten the final product after disgorgement.

The first addition can create problems. If too much sugar is added, resulting in a pressure in the bottle that is too high (danger of explosion by popping the crown seal or at disgorgement) or the opposite (not enough fizz). This book gives clear instructions about alternatives.

The fermentation liqueur (tirage liqueur) is made from cane sugar dissolved in wine a week or so prior to pouring into the bottle, giving time for the sucrose to invert (change to a sugar that yeasts can use as a food source). It should not ferment in storage because the sugar levels are too high. To make 1L of fermentation liqueur, add 0.5 kg cane sugar into 0.69L of wine base. Add some citric acid to assist in sugar inversion and adjust the pH to that of the base wine. For smaller volumes, change the proportions.

The amount of liqueur you add depends on the pressure you want in the bottle. A graph is given in the text outlining the CO2 (g/L) and pressures (kPa) for various temperatures (from –5C to 25C). You select the pressure you want for a given temperature and insert the required number of grams of sugar per litre of wine. For example, for a final pressure of 400kPa (4 atmospheres) at 20C then 7.25 g/L of carbon dioxide are required. You may decide to seek a pressure of 500-600kPa in recognition that some will be lost when you disgorge the sediment. For the moment I’ll stick with 400kPa.

1 g of sugar produces 0.49g of CO2. Therefore, for 7.25g of CO2 you need 7.25/0.49 = 14.8g of sugar per litre of wine. Because 1L of liqueur contains 500g of sugar (see above), the volume of liqueur required is 14.8/0.5 = 29.6ml of liqueur per litre of wine. ...

[That’s all theory. If I added the amount of sugar they do in commercial wineries I think I would blow up my house. After some experimenting now add eleven grams of sugar to each bottle and squirt in some re-hydrated yeast solution with a hypodermic syringe (with the needle removed). Then I crown seal the bottle. This seems to generate enough bubbles for an acceptable sparkle but not run the risk of explosions. I have found it useful to use a receptacle that holds exactly 11 g as a measure which I dip into the bag of sugar and then I don’t have to worry about scales at this messy time. I use granular sugar and toss it in using a funnel. I suppose it would be better to use a sugar solution, but I find the sugar dissolves pretty quickly anyway.] ..... ^

If you want to be more precise, the addition of the 29.6mL per 1L of wine will increase the volume of the blend and this can be allowed for. The formula for this is as follows:

V (wine) x V (liqueur) = Volume of liqueur

V(wine) – V (liqueur)

e.g. : 1,000/(1,000 – 29.6) = 30.5 litres of liqueur required where V (wine ) is the volume of wine and V (liqueur) is the calculated apparent volume.

When this is fermented to dryness the low pH and the presence of carbonic acid makes the wine taste very dry and further sugar is added to personal taste (from 2.5 to 80g/L). Less that 15g/l will still give a Brut sparkling.

Dissolving at a rate of 6.26g in 6.12mL of wine normally makes this final liqueur. However other additions are also possible: For example to make 1L of liqueur, mix together and stir till dissolved:

Sucrose 625g

Brandy 40mL

Matured Wine 570mL

Citric Acid 5g

To prevent microbial activity and oxidation in the bottle of sparkling wine, add SO2 to the liqueur to bring the level of SO2 in the final bottle of wine to 35mg/L. (You can work out the proportions required for your homework)....^

If you are still with me, the calculation of the final liqueur addition is as follows: To liqueur a dry (brut) wine to 1% sugar (or 10g/L) with a liqueur containing 625g/L of sucrose, the calculation is as follows. For a 750mL bottle of wine, the quantity of sucrose required = 10/1,000 x 750 = 7.5 gm/bottle.

If you are using liquor containing 625g/L sucrose, the required volume of liqueur containing 7.5g sucrose is: 1,000/625 x 7.5 = 12mL of liqueur for each 750mL bottle.

2. Disgorgement

Part 1 exposed the depths to which an amateur winemaker must descend to achieve a clean bottle of sparkling wine. Part 2 are my notes on the expert account outlined in the Reference book.

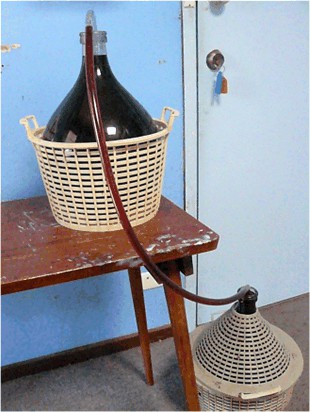

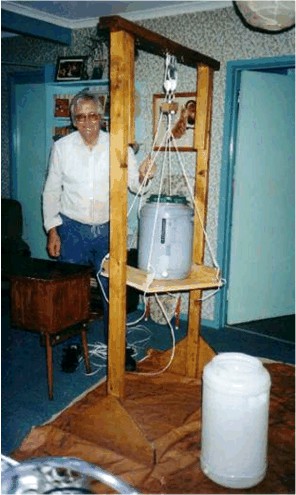

The lees (dead yeast cells) that have accumulated in the neck of the bottle of sparkling wine that has undergone a secondary fermentation in the bottle needs to be removed and this process is called disgorgement. Disgorging is a skilful operation when carried out manually. Commercially, the neck of the bottle is usually snap-frozen and the ice plug is expelled, along with the lees.

The book also describes a technique used when bottles are at cellar temperature and no ice plug is used. When cork-sealed bottles are disgorged, the bottle is held at about 45 degrees below the horizontal with the gas bubble held in the shoulder of the bottle. Then, using a special pair of pliers, the clip is levered off the cork, holding the cork with the index finger of the other hand. The cork is then allowed to be slowly forced out of the bottle until explosion when the bottle is uprighted with a twisting motion to about 45 degrees above the horizontal, to position the gas bubble between the liquid in the bottle and the deposit. The deposit is blown out of the bottle by the pressure and the bottle is given a sharp tap with the plier that induces the wine to foam slightly to wash any remaining deposit out of the bottle.

So much for the theory and practice of experts! We now come to the pornographic processes of the amateur. ..^

I use crown seals for the secondary ferment (and for the final product – the cork and wire and metal dressing are aesthetic, but the crown seal is inexpensive and does the job). As described above, I tried the 45-degree tilt and moved the bubble to the shoulder just as I released the crown seal. And yes, I did manage to discharge the sediment so I have managed to achieve the required result, I suppose. But my mental image of the process described in the book has never matched my reality.

I do not have the experience to remove the crown seal with precision. Some flip off quickly, some slowly. The danger is in a hesitation in the movement, and believe me there is real reason for hesitation. Too quick a release results in massive foaming and you lose half a bottle of precious wine. Too slow and you waste the energy of the fizz to remove the sediment. If there is any hesitation in the movement while the cap comes off, the pressure in the bottle is released while the cap is only partially released. The plug of sediment and wine is expunged in foam caused by the bubble in the bottle and the pressure of CO2 in the wine; it hits the partially released cap and sprays with considerable force and magnitude back onto the disgorger and onto everything behind him. His clothes are saturated and for a considerable distance behind him, the surroundings are doused in wine.

After many tries, I find the only practical way to achieve disgorgement is to select a warm day in summer and to take my bottles into the garden. I find an area not too close to the house, but with a broad area of garden behind me, not too close to the neighbors. I strip to my underpants (I have a false sense of modesty) and proceed to flip off the crown seals with the utmost care and precision. I like to refer to these sessions as disgorgement, rather than disgorging because it lends an artistic flavour to an otherwise very ordinary experience.

In every disgorgement I have carried out, I end up with the garden covered in spray and myself in the shower before I can approach the task of re-dressing myself and topping up and re-sealing the bottles so that I can achieve the necessary clarity of sparkling wine. The neighbours have threatened to sell tickets for the event. Such is my passion for homemade wine. There can be no greater sacrifice. ...^

Postscript

I now buy a small amount of dry ice in an Esky and invert the bottles into it (for about 30 seconds). That’s enough to freeze the wine in the neck of the bottle. Then I flip off the crown seal and the plug of ice (with sediment) shoots into the neighbour’s yard. It’s less messy but you still need a shower at the end. Wear safety glasses and keep the bottle facing away from your face. If the plug gets stuck you can prod it with a screwdriver to help it fly out but don’t point it towards your face. The mobile plug of ice is dangerous. It would be safer to work with the bottle behind a Perspex screen but I haven’t used one.

Reference:

Armstrong. D Rankine B and Linton G. 1994 Sparkling Wines. The Technology of Their Production In Australia Winetitles Adelaide ACC 291991 BRN 173284 NMIT Library: ARM 663.2240994

Back to top